Digitising Manufacturing: what does it mean?

The Digitisation of the manufacturing sector is key to optimise processes, provide safer workspaces, and gain higher consistency.

As industry demands become more sophisticated and complex, manufacturing requires greater levels of data analysis and interconnectivity. Internet of Things technology, such as trackers and sensors, together with reliable and secure large-scale wireless networks, are ideal for that.

Many manufacturing firms have already started using IoT devices in their operations and this Digital Transformation will only continue to grow. That is because they give the possibility to collect important information about the plant, the equipment, and the machinery, transferring that data into a centrale system.

These are some of the possible applications for Smart Manufacturing:

- Operational efficiency maximisation

- Asset and building systems tracking

- Alerting devices

- Vibration/movement monitoring

- Working conditions optimisation

- Smart waste management

- Identification of new areas of savings

- Machinery performance monitoring

- Energy monitoring

- Environmental monitoring

How it works

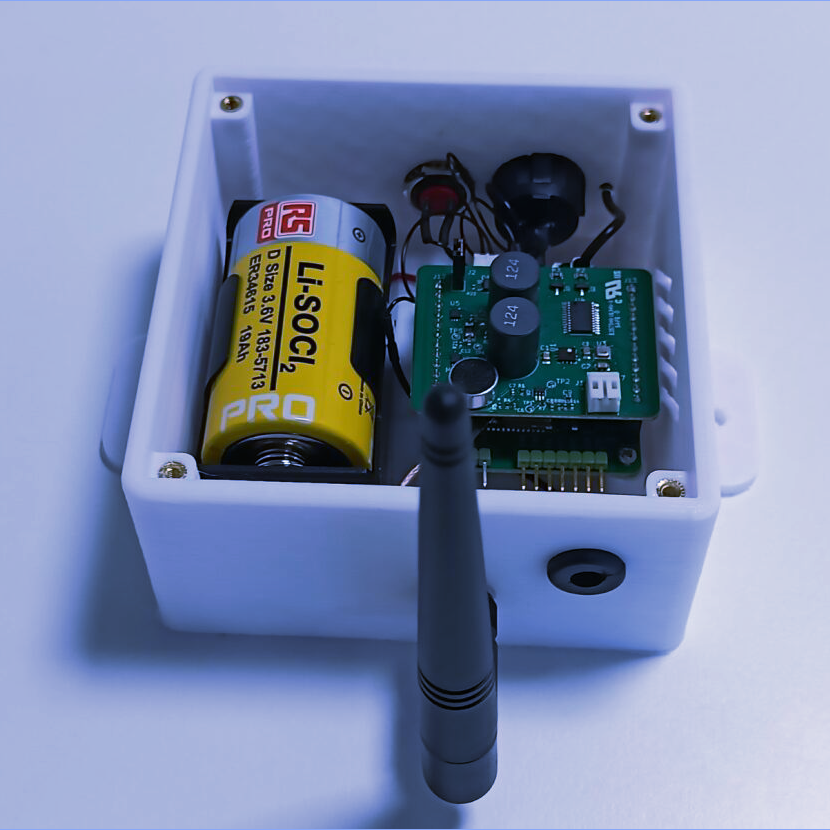

A Smart Manufacturing system typically consists of sensors, a gateway and a software platform. Sensors could be measuring vibrations, water, temperature, air quality and more, dependending on the specific project needs; adata is then sent to the gateway which transmits everything to a server. All information is then shown on a platform in a user friendly way.

Every facility has their own requirements.

At Move-X we help companies develop technology-driven approaches to improve manufacturing operational efficiency, offering solutions that are future-proof and that can suit a variety of environments.